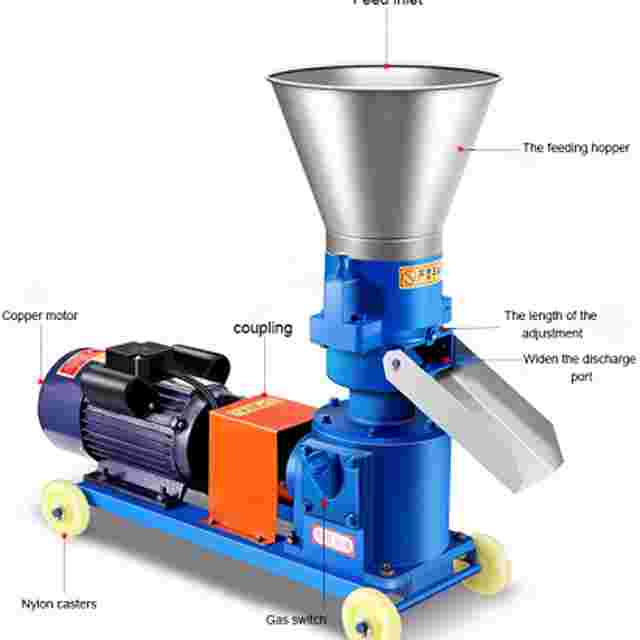

Pelletizing Machine

A mechanical pelletizing machine is used for converting feed ingredients that are in mash form into dry pellets, resulting in strong, smooth pellets that are good for feeding fish. A pellet mill, also known as a pellet press, is a type of mill or machine press used to create pellets from powdered material. Pellet mills are unlike grinding mills, in that they combine small materials into a larger, homogeneous mass, rather than break large materials into smaller pieces.

Features/Benefits of Mechanical Pelleting Machine

- It utilizes steam, pressure, and temperature.

- It uses dies to form the pellets.

- Sinking Fish Feed Pellets also known as hard pellets, are more economical.

- The sinking feed will have water stability of up to an hour, and will gradually sink and settle on the bottom if uneaten.

- Since ingredients are pressed together, it makes it impossible for the fish to selectively eat the ingredients they want.

- Sinking pellets are adapted to mechanical feeding and can be handled considerably without deterioration.

- Sinking pellets are sometimes used in winter when the fish do not regularly surface.

- Also by pelleting some feeds it can be avoided to harm some ingredients which do not like the extrusion process.

- Pelleted feed made by a feed pellet machine can make animals have better performance than a meal ration.

- The feed pelletizer is especially beneficial for small-scale production as it is lightweight, has a simple structure, consumes low power, and is very affordable.

- The key components are the die and roller which are made of high-quality alloy material and are well treated with heat to ensure the durability of the machine.

- The machine is very easy to operate, and it produces very low noise.

Reviews

Clear filtersThere are no reviews yet.